Industrial Operations X is accelerating the transformation from automated to adaptive production.

Our Industrial Operations X portfolio combines multiple tools to deliver powerful IoT results. It helps you—across all industries—accelerate production processes by making them adaptive, people-centric and holistically integrated. With this new approach to operations and smart manufacturing, you are better equipped to face ever-changing industry demands, business models and workforces.

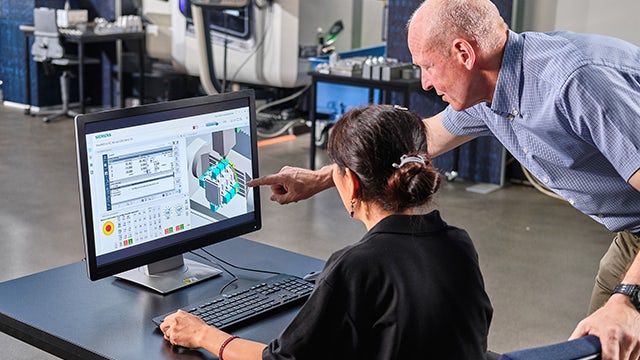

As part of the Industrial Operations X portfolio, Insights Hub delivers business value from IoT data, while the combined IoT capabilities of Industrial Operations X enables customers, partners and organizations across the Siemens Xcelerator ecosystem to build industry-specific applications.